|

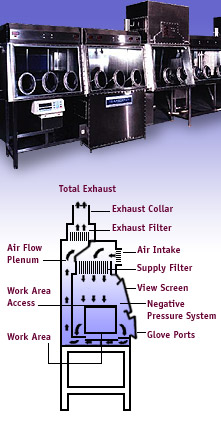

Class III Biological Safety Cabinet Characteristics

- Gas-tight absolute containment enclosure

- Offers product, personnel and environmental protection

- Minimum air intake velocity through a glove port is 100 fpm (0.51 m/s), if the glove is cut or removed

- Air must be exhausted to the outdoors

- Integral equipment allows the safe introduction and removal of materials

- Exhaust air is treated by double HEPA filtration or HEPA filtration and incineration

- Operation in cabinet performed through rubber gloves

- Operates under negative pressure of at least 0.5" w.g. (124 Pa)

- Supply air is HEPA filtered

- Must be connected to a double door autoclave and/or chemical dunk tanks to sterilize or disinfect all exiting materials

|

|

![]()